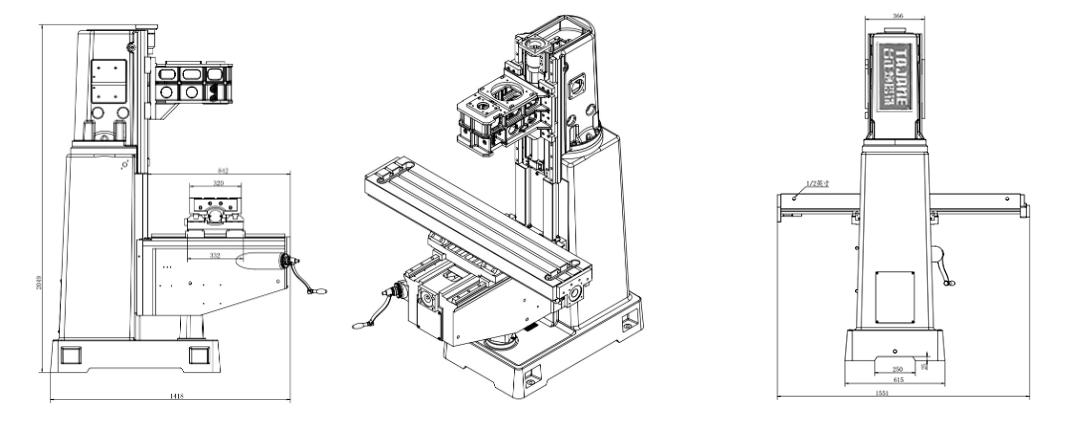

CNC MILLING MACHINE MX-5SL

Optomechanical drawings

The drawings of Taizheng CNC turret milling machine, derived from Taiwan's design, contain core elements such as mechanical parameters and electrical diagrams. The machine bed is made of Meehanite cast iron, processed through special techniques, and has excellent rigidity; the spindle is precisely configured with strong cutting force, suitable for processing precision molds, parts and components, etc.

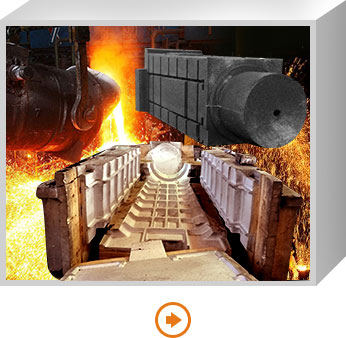

Manufacturing Process

The TAJANE turret milling machine is manufactured using Taiwan’s original drawings, and the casting is done using the Mihanna casting process with TH250 material. It is manufactured through natural failure, tempering heat treatment, and precision cold processing.

Meehanite casting process

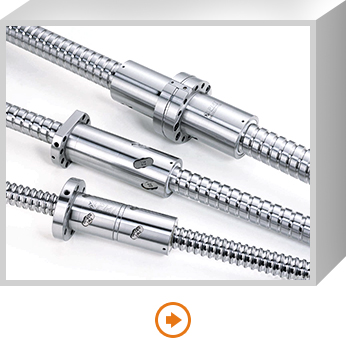

Ball screw Linear slide rail

Spindle made by KENTURN

HERG Lubrication Pump

Pull rod Locking machine

Coupling made by NBK Japan

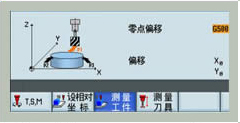

Numerical control system SIMMENS 808D

HDW Tool magazine

High precision chuck assembly

Electrical Safety

The electrical control box has dust-proof, waterproof, and anti leakage functions. Using electrical components from brands such as Siemens and Chint. Set up 24V safety relay protection, machine grounding protection, door opening power-off protection, and multiple power-off protection settings

Feed shaft Spindle tool Rate adjustment knob

Graphic programming Colour display screen

Multilingual Interface

Power off switch

Master switch Power Indicator Lamp

Earthing protection

Emergency stop button

Sturdy Packaging

The machine tool’s interior is vacuum-sealed for moisture protection, and its exterior packaged with fumigation-free solid wood and fully enclosed steel strips to ensure transport safety. Free delivery is offered at major domestic ports and customs clearance ports, with safe transport to all global regions.

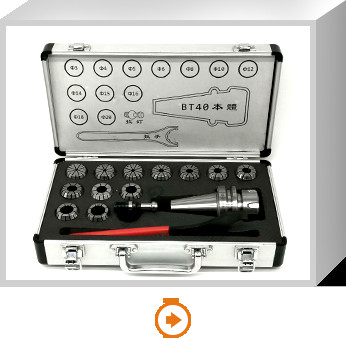

Milling machine accessories meet different processing needs

Standard equipment: Nine major accessories are included as gifts to meet customers’ different processing needs.

Present nine kinds of wearing parts to solve your worries

Consumable parts: Nine key consumables are included for peace of mind. You may never need them, but they’ll save time when you do.

| Bed dimension | 1473 x 320mm |

| X axis of worktable stroke | 950mm/980mm(limit stroke) |

| Sliding saddle stroke (Y axis) | 380mm/400mm(limit stroke) |

| Spindle box stroke (Z axis) | 415mm |

| Elevator manual stroke | 380mm |

| Table load bearing | 280KG(full stroke)/350KG(Middle of the working table400mm) |

| T-slot size | 3 x 16 x 75mm |

| Principal axis | BT40- ∅120 Taiwan Keychun |

| Main shaft speed | 8000rpm |

| Spindle power | 3.75KW(rated) 5.5KW(overload) |

| voltage | 380V |

| frequency | 50/60 |

| Positioning accuracy / repeat positioning accuracy | Middle of the working table400mm:0.009mm/±0.003mm |

| Full stroke950mm:0.02mm、arbitrary300mm/0.009mm | |

| Feed motor power | X、Y/7Nm Z/15Nm with brake |

| Fastest moving speed | X, Y axis/12m/min Z-axis/18m/min |

| Ball wire rod type X shaft | 3208 Taiwan original |

| Ball wire rod type Y shaft | 3208 Taiwan original |

| Ball wire rod model Z shaft | 3205 Taiwan original |

| Rail X axis | 35Ball wire track wholly owned by Taiwan |

| Line rail Y axis | 35Ball wire track wholly owned by Taiwan |

| Rail Z axis | 30Ball wire track wholly owned by Taiwan |

| clutch | NBKJapanese |

| Knife cylinder | Haocheng Taiwan |

| tool magazine | 12Bucket type Taiwan brand |

| system | Siemens, Germany808D system |

| Machine tool shape dimension | 2000x1920x2500 |

| weight | 2600kg |

| Positioning accuracy X-directional full stroke / repeat positioning accuracy | 0.02mm/0.012mm |

| Positioning accuracy / repeat location of 400mm in the middle of workbench | 0.009mm/0.006mm |