Jet knee milling machine MX-5HG

Purpose

The MX-5HG vertical milling machine is equipped with a three-axis grating ruler, X and Y powerful electronic traversing systems, a Z-axis rapid lifting function, a 5P high-power motor for the spindle, and the spindle taper is NT40. Vertical milling machines are widely used in the processing of complex parts, featuring high speed, high precision, and high efficiency.

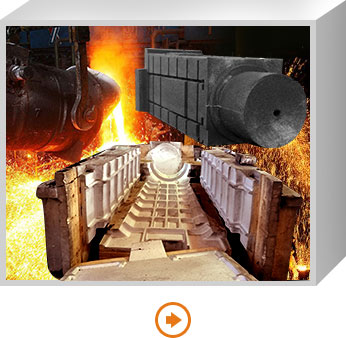

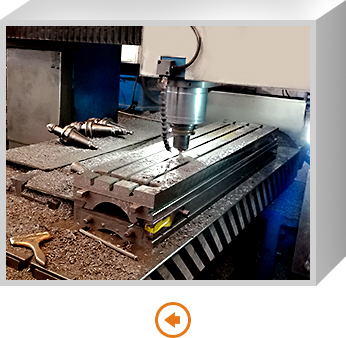

Manufacturing Process

TAJANE turret milling machines are manufactured according to original Taiwanese drawings. The casting adopts the Meehanite casting process with TH250 material, and is produced through natural aging, tempering heat treatment, and precision cold working.

Mihanna Casting Technology

Elimination of internal stress

Tempering heat treatment

Precision machining

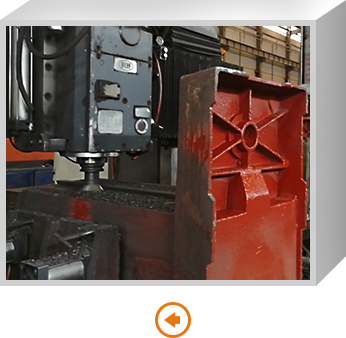

Lifting table processing

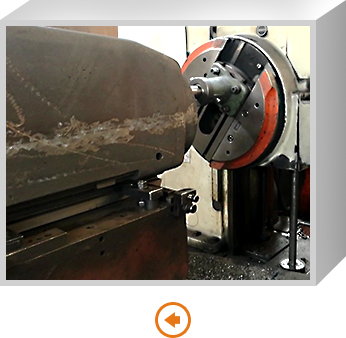

Lathe processing

Cantilever machining

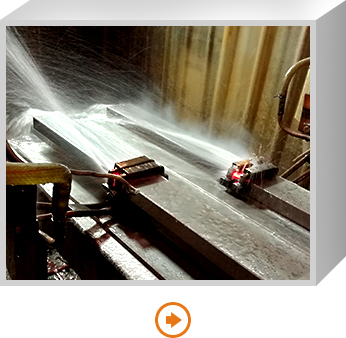

High frequency quenching

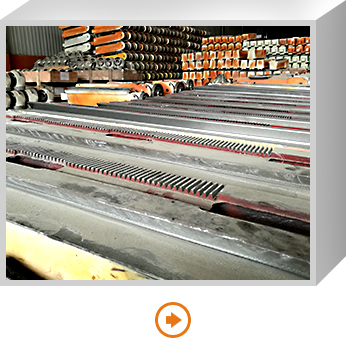

Fine carving

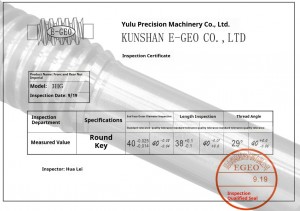

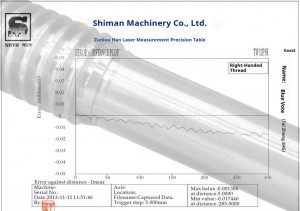

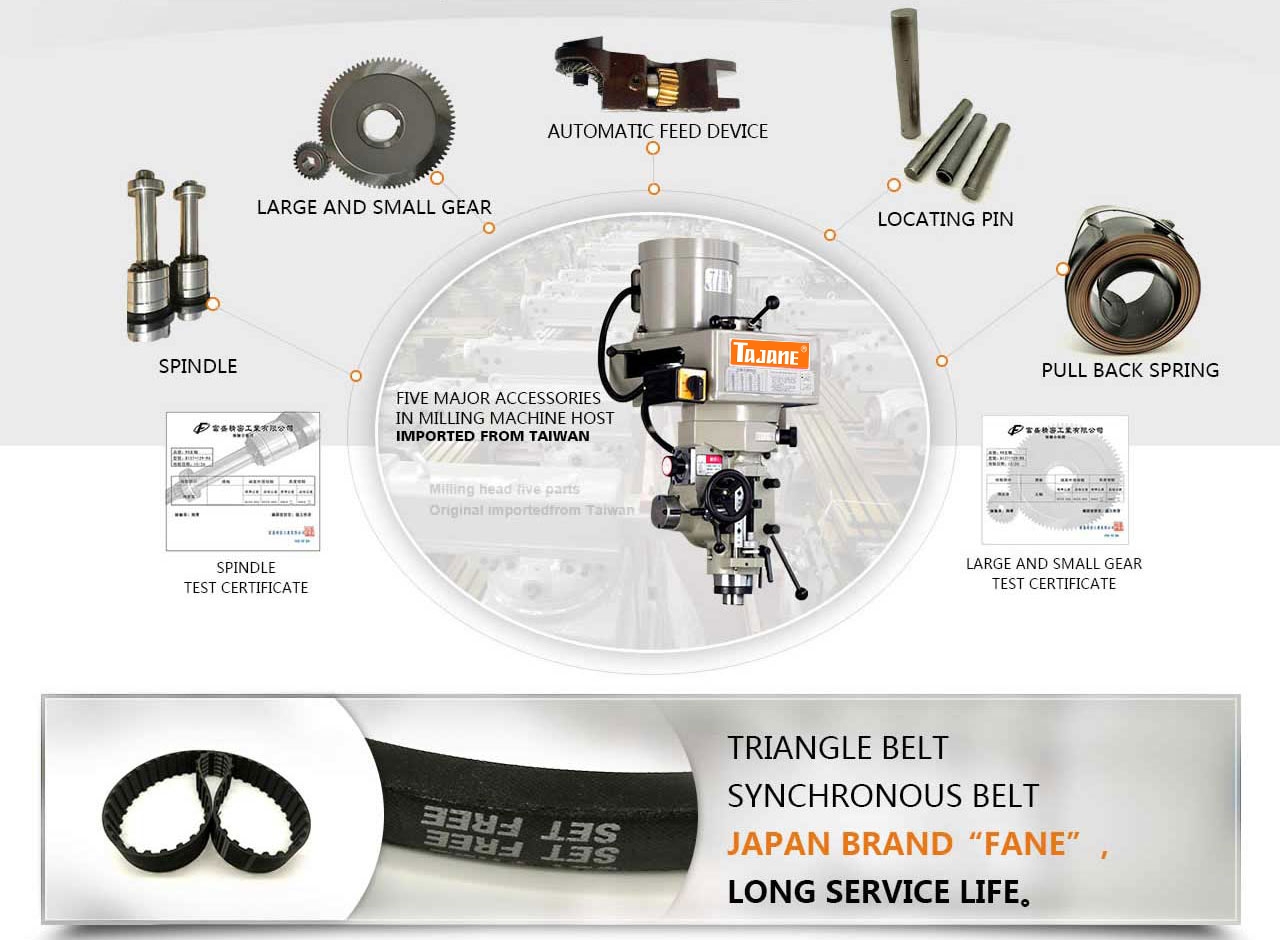

Premium Components

Taiwan original precision components; X, Y, Z three-way lead screws of Taiwan brand; The five major components of the milling head are purchased from original Taiwan sources.

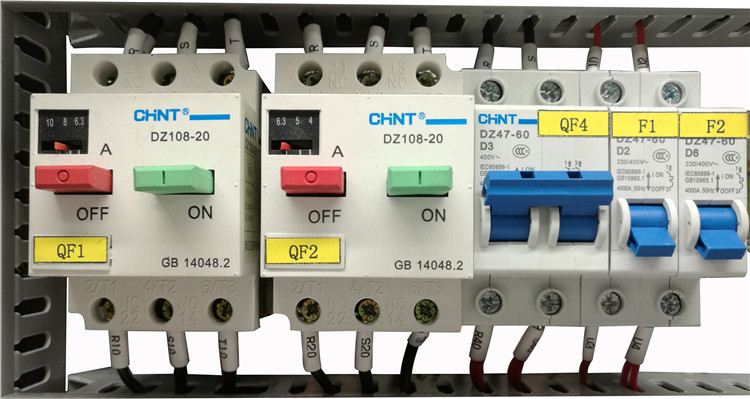

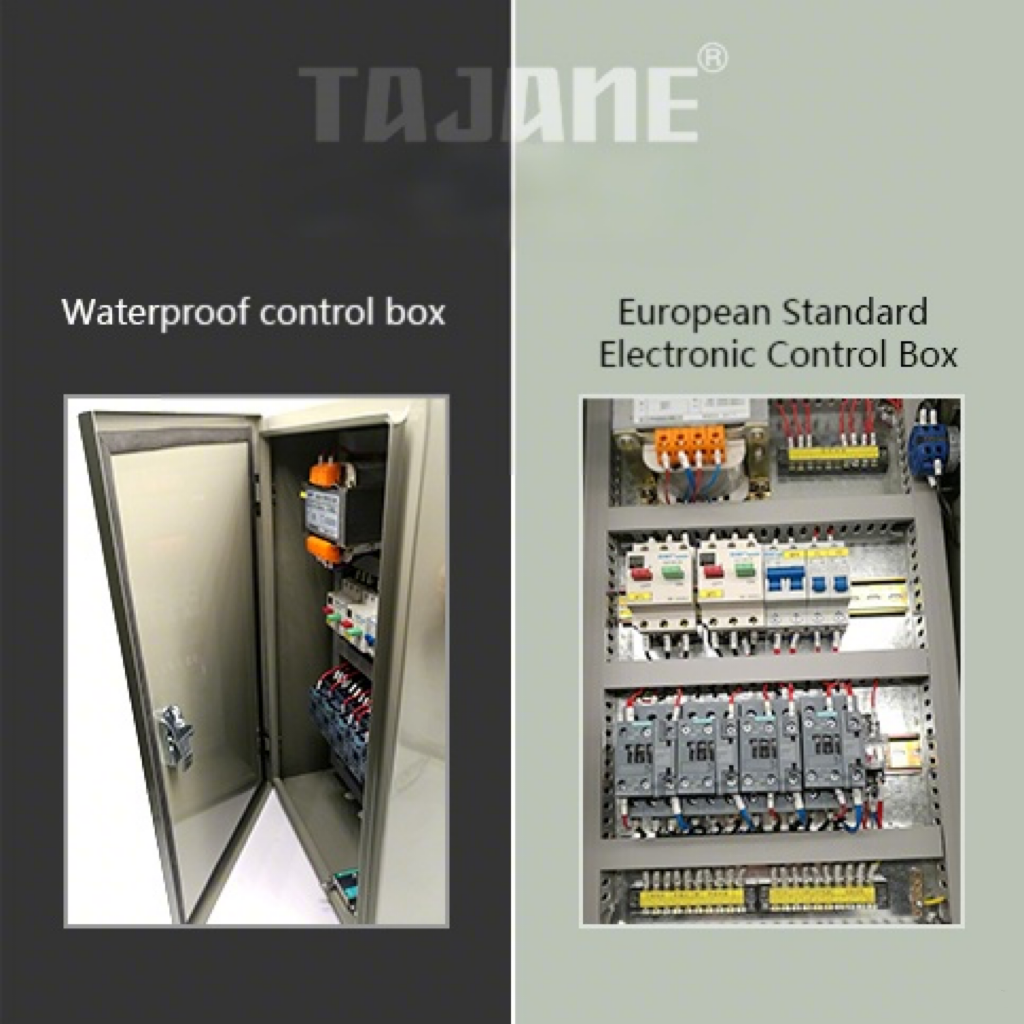

Electrical Safety

The electrical control box has dust-proof, waterproof, and anti leakage functions. Using electrical components from brands such as Siemens and Chint. Set up 24V safety relay protection, machine grounding protection, door opening power-off protection, and multiple power-off protection settings

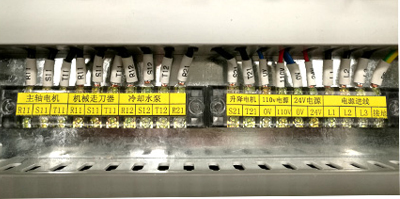

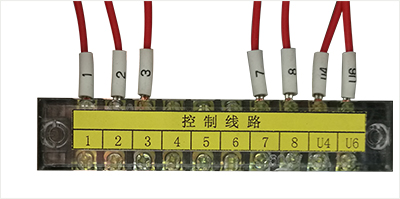

Using European Standard Cable

Main cable2.5MM², Control cablel 1.5MM²

Electrical components are Siemens And CHNT

Identification clear

Convenient maintenance

Earthing protection

Door s open and power will be cut off.

Press emergency stop Power cut off.

Power off switch

Master switch Power Indicator Lamp

Earthing protection

Emergency stop button

Sturdy Packaging

The machine tool’s interior is vacuum-sealed for moisture protection, and its exterior packaged with fumigation-free solid wood and fully enclosed steel strips to ensure transport safety. Free delivery is offered at major domestic ports and customs clearance ports, with safe transport to all global regions.

Milling machine accessories meet different processing needs

Standard equipment: Nine major accessories are included as gifts to meet customers’ different processing needs.

Present nine kinds of wearing parts to solve your worries

Consumable parts: Nine key consumables are included for peace of mind. You may never need them, but they’ll save time when you do.

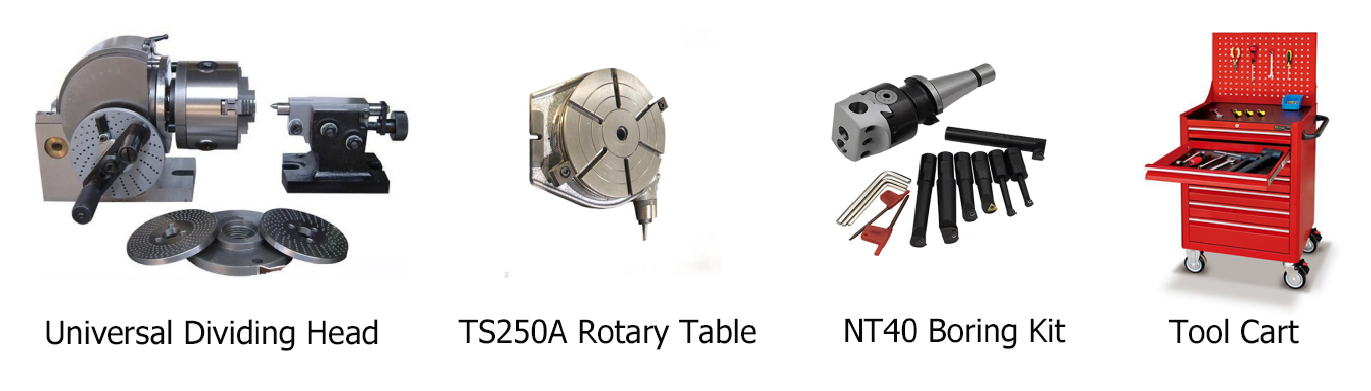

Machine tool additional equipment, suitable for various processing

Additional equipment: Auxiliary tools expand functionality for special/complex processing (optional, extra cost).

| Model | MX-5HG |

|---|---|

| Strength | |

| Network voltage | Three-phase 380V (or 220V, 415V, 440V) |

| Frequency | 50Hz(or 60Hz) |

| Main drive motor power | 5HP |

| Total power / current load | 5kw/7.5A |

| Machining parameters | |

| Worktable size | 1372×305mm |

| X-axis travel | 900mm |

| Y-axis travel | 420mm |

| Z-axis travel | 380mm |

| Workbench | |

| Workbench T-slot | 3×16×65mm |

| Maximum load capacity of workbench | 400kg |

| Distance from spindle end face to workbench | 500mm |

| Distance from spindle center to guideway surface | 210mm |

| Milling head spindle | |

| Type of spindle taper | NT40 |

| Spindle sleeve stroke | 120mm |

| Spindle feed speed | 0.04;0.08;0.15 |

| Outer diameter of spindle | 85.725mm |

| Milling head speed | |

| Spindle speed stages | 16 stages |

| Speed range | 70-5440 rpm |

| Number of steps (low range) | 70、110、180、270、600、975、1540、2310rpm |

| Number of steps (high range) | 140、220、360、540、1200、1950、3080、5440rpm |

| Structure | |

| Swivel milling head | ±90° left and right, ±45° front and back, 360° cantilever |

| Guideway type (X, Y, Z) |

▲ ■ ■

|

| Ram extension arm | 520mm |

| Lubrication method | Electronic automatic lubrication |

| Aspect | |

| Length | 1820mm |

| Width | 1750mm |

| Height | 2000mm |

| Weight | 1700kg |