Vertical machining center VMC-850A

Purpose

TAJANE vertical machining center VMC-850 series is specially designed for processing complex parts such as metal plates, disc-shaped parts, molds and small housings. The vertical machining center can perfectly perform operations like milling, boring, drilling, tapping and thread cutting, providing solutions for metal parts processing in various fields

Product Usage

TAJANE vertical machining center VMC-850 series can be used to process precision parts of 5G products, and can also meet the processing needs of shell parts, auto parts and various mold parts. In addition, it can realize high-speed processing of box-type parts, improving processing efficiency and processing accuracy.

Vertical machining center 5G precision parts processing

Vertical machining center for batch processing of shell parts

Vertical machining center for auto parts processing

Vertical machining center for box-type parts processing

Vertical machining center for mold parts processing

Product casting process

For the CNC VMC-850 vertical machining center series, the castings adopt the Meehanite casting process with the grade TH300, which features high strength and high wear resistance. The interior of the castings of the VMC-850 vertical machining center is designed with a double-wall grid-like rib structure. In addition, the natural aging treatment of the bed and column of the VMC-850 vertical machining center effectively improves the accuracy of the machining center. The worktable cross slide and base can meet the requirements of heavy cutting and rapid movement, providing users with a more efficient and stable processing experience.

How to reduce the non-conforming rate of

vertical machining center castings to 0.3%

CNC vertical machining center,with a double-walled grid-like rib structure inside the casting.

CNC vertical machining center, the spindle box adopts optimized design and reasonable layout.

Vertical machining center bed and column undergo natural aging for higher precision.

CNC vertical machining center, table cross slide and base, to meet heavy cutting and rapid movement

Product assembly process

In the VMC-850 vertical machining center, the stability of the machine tool's precision and rigidity are enhanced through the scraping of contact surfaces of components such as the bearing seat, the contact surfaces of the worktable nut seat and slider, the contact surface between the spindle box and the spindle, and the contact surfaces of the base and column. At the same time, it eliminates internal stress in the machine tool, reduces friction, and prolongs the service life of the vertical machining center.

How is the precision of a vertical machining center "scraped out"?

① Scraping and lapping of the bearing seat of the vertical machining center

② Scraping and lapping of the contact surfaces between the worktable nut seat and the slider

③ The contact surface between the headstock and the spindle of the vertical machining center

④ Scraping and lapping of the contact surface between the base and the column

Accuracy inspection process

All products in the CNC VMC-850 vertical machining center series undergo precision inspection tests before leaving the factory. These include geometric accuracy inspection, positioning accuracy inspection, test cutting accuracy inspection, and laser interferometer accuracy monitoring. Each step requires multiple measurements to calculate the average value, so as to reduce accidental errors, ensure the results, and achieve high-speed, high-precision, and high-efficiency machining effects.

Workbench Accuracy Test

Opto-mechanical inspection

Verticality Detection

Parallelism Detection

Nut Seat Accuracy inspection

Angle Deviation Detection

Design features

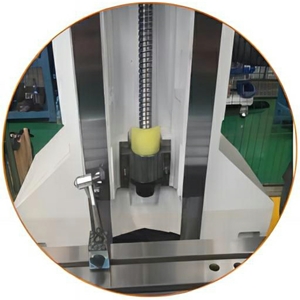

The main components of the machine tool body for the VMC-850 series vertical machining centers are made of HT300 high-strength gray cast iron, undergoing heat treatment,natural aging and precision cold processing. It adopts a herringbone column,with a counterweight mechanism for the Z-axis. The guide rails are manually scraped, enhancing rigidity and avoiding machining vibration.

Video of vertical machining center castings

Vertical machining center light machine

Vertical machining center Bearing Spindle

Vertical machining center Bearing

CNC vertical machining center, Lead screw

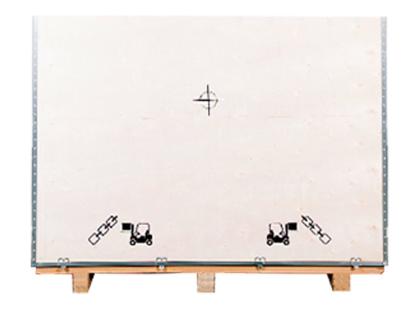

Sturdy Packaging

The entire series of CNC VMC-850 vertical machining centers are packaged in fully enclosed wooden cases, with moisture-proof vacuum packaging inside the cases. They are suitable for long-distance transportation such as land and sea transportation. Each vertical machining center can be safely and punctually delivered to all parts of the world.

Locking connection, firm and tensile.

Free delivery to major ports and customs clearance ports nationwide.

Removal of marks

Locking connection

Solid wood central axis

Vacuum packaging

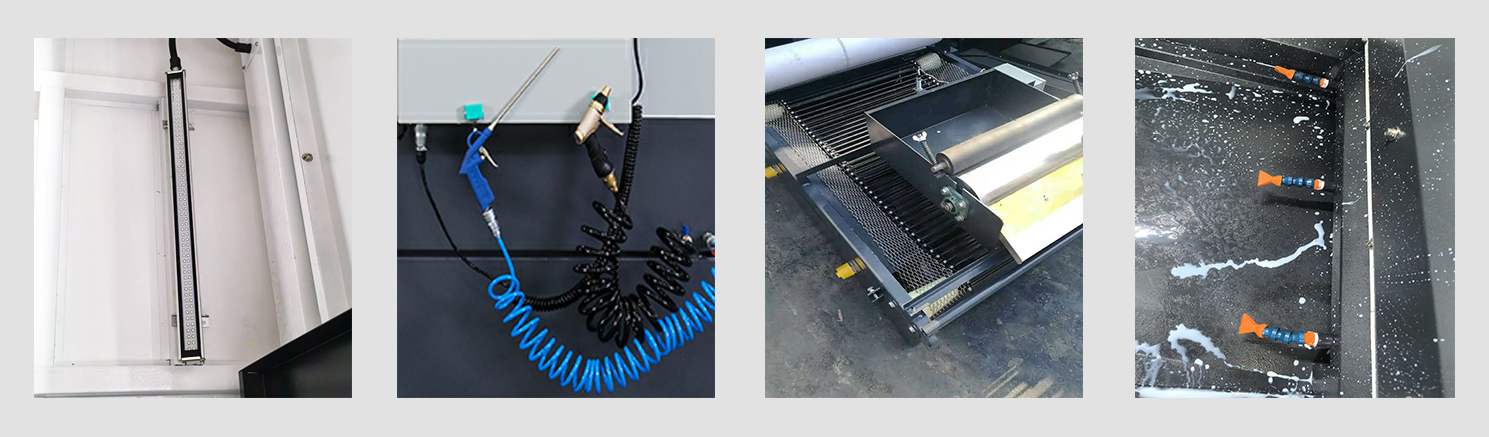

Standard equipment

The standard configuration of the full series of VMC-850 Vertical Machining Centers is the key to ensuring the stable realization of core machining functions. It establishes guarantees from three core dimensions: safety protection, reliable operation, and easy operation. It is suitable for meeting the needs of conventional metal cutting processes and lays a foundation for production efficiency and machining quality.

Additional equipment

I. For the full range of VMC-850 vertical machining centers, optional spindles are available as additional equipment:

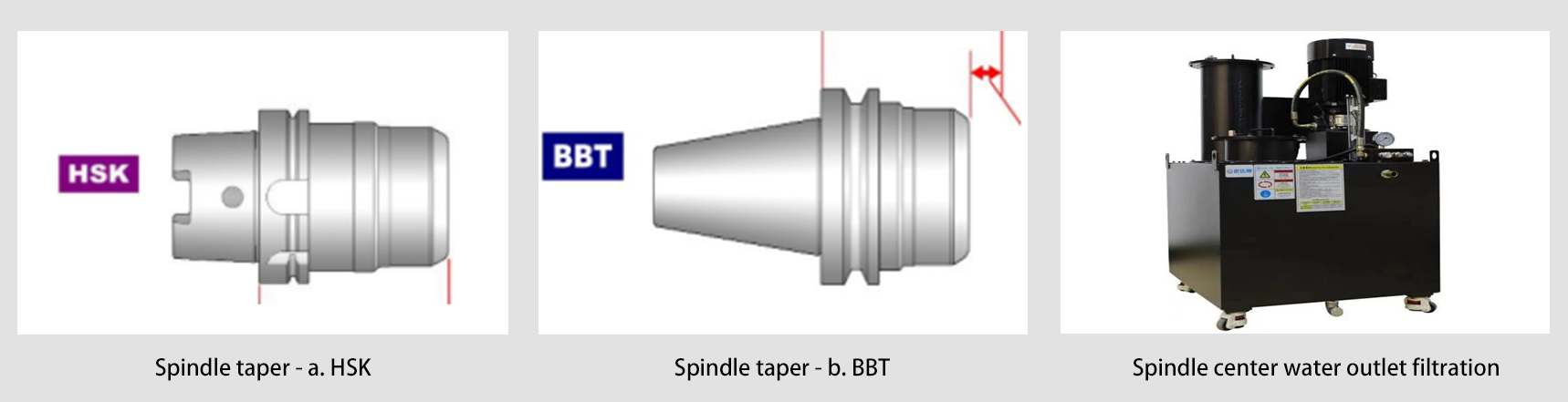

II. For the full range of VMC-850 vertical machining centers, spindle taper types and spindle center water outlet filtration systems are available as additional equipment:

III. For the full range of VMC-850 vertical machining centers, an optional tool setter is available as additional equipment:

IV. For the full range of VMC-850 vertical machining centers, optional linear scales and workpiece measuring OMP60 are available as additional equipment:

V. For the full range of VMC-850 vertical machining centers, an optional tool magazine is available as additional equipment:

VI. For the full range of VMC-850 vertical machining centers, optional simple oil-water separators and oil mist collectors are available as additional equipment:

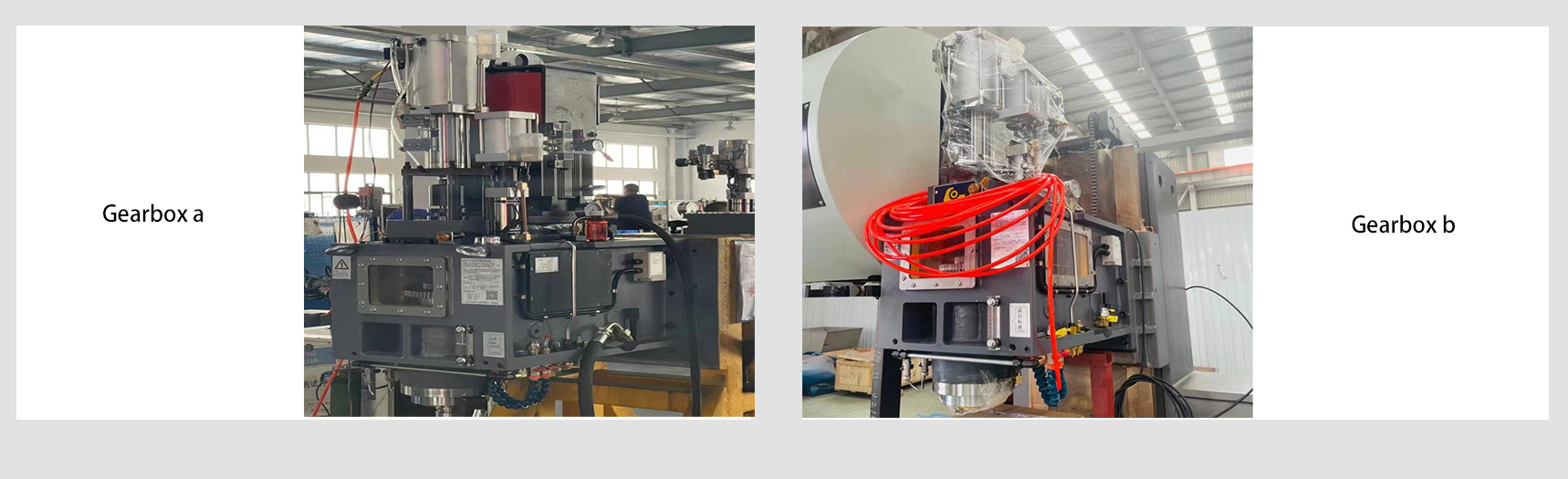

VII. For the full range of VMC-850 vertical machining centers, an optional gearbox is available as additional equipment:

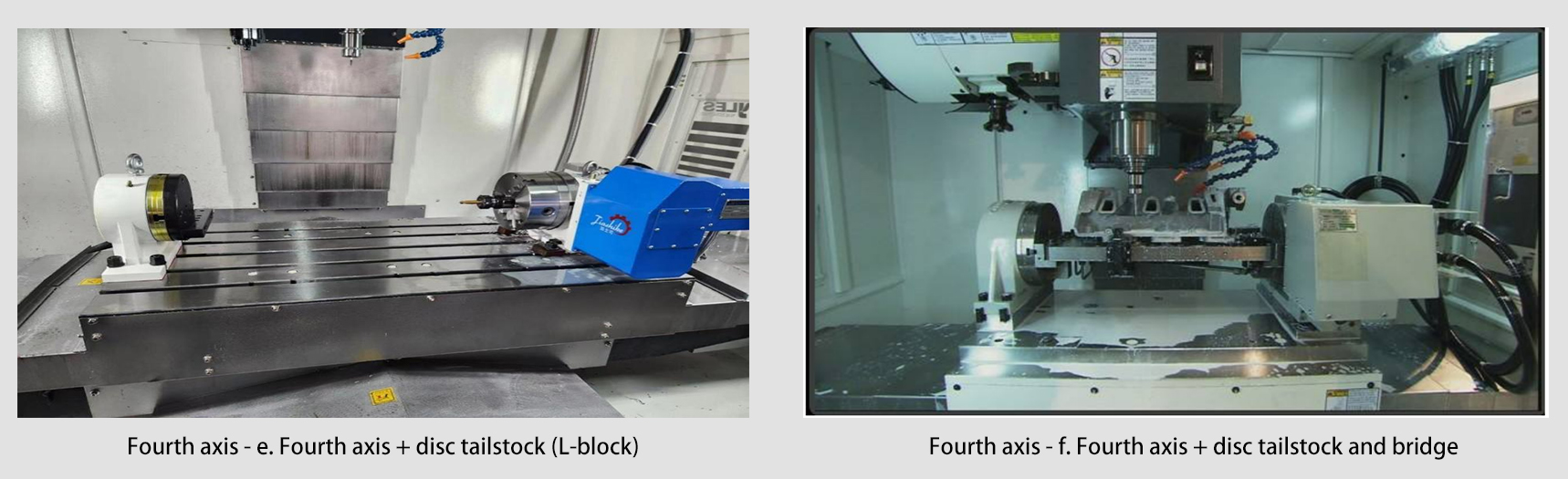

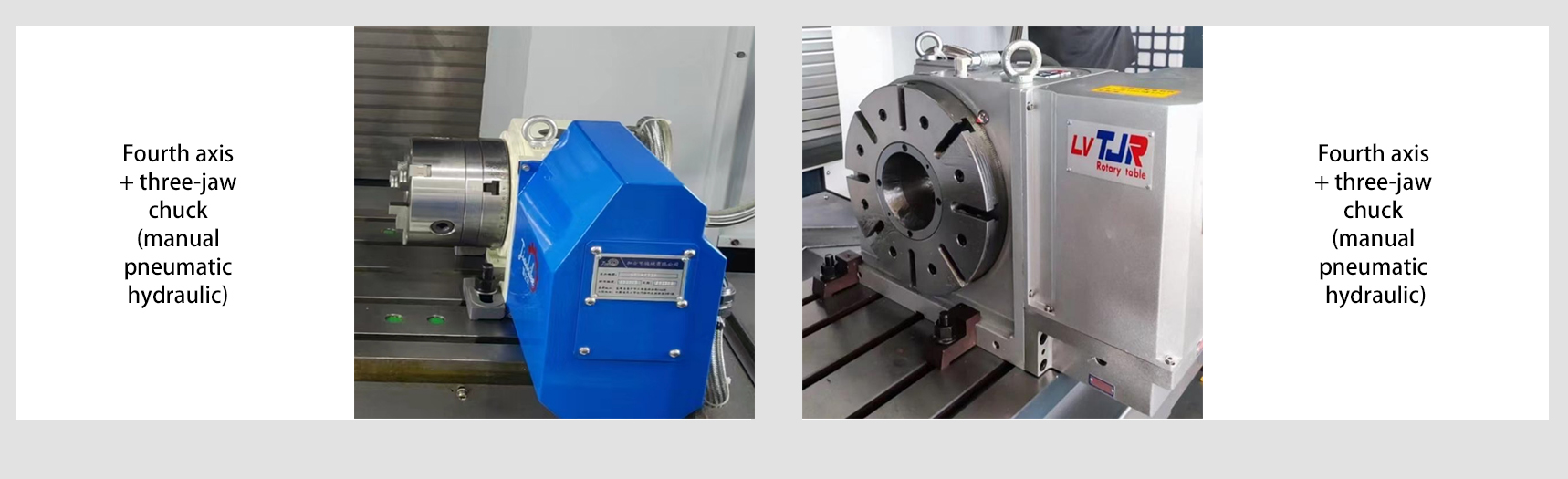

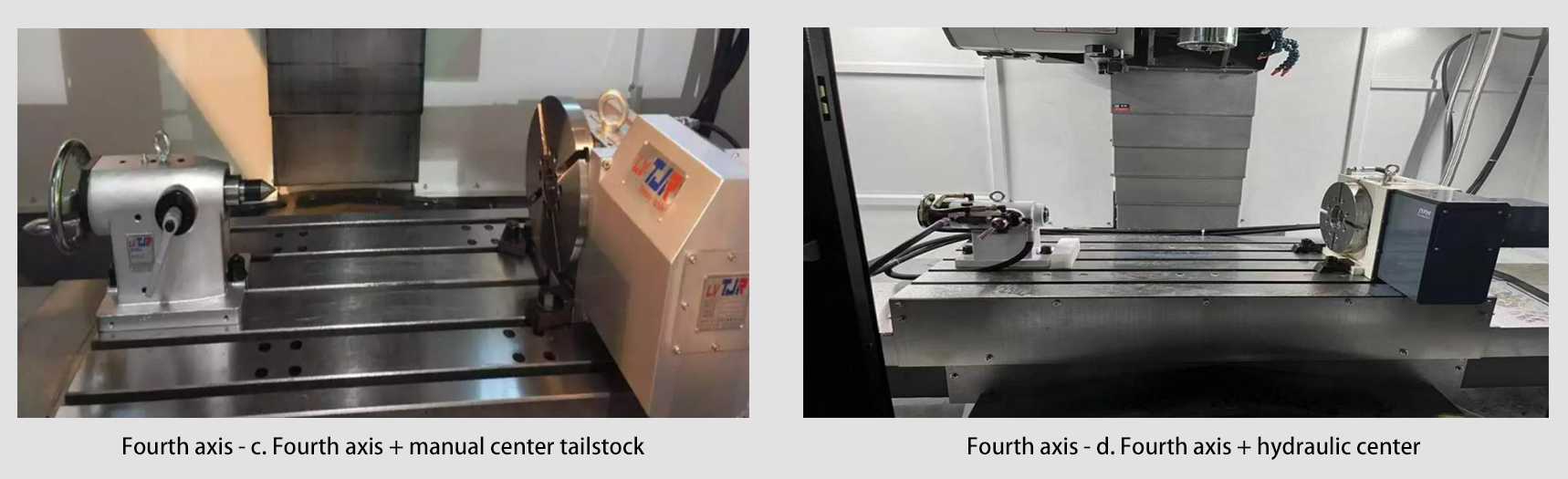

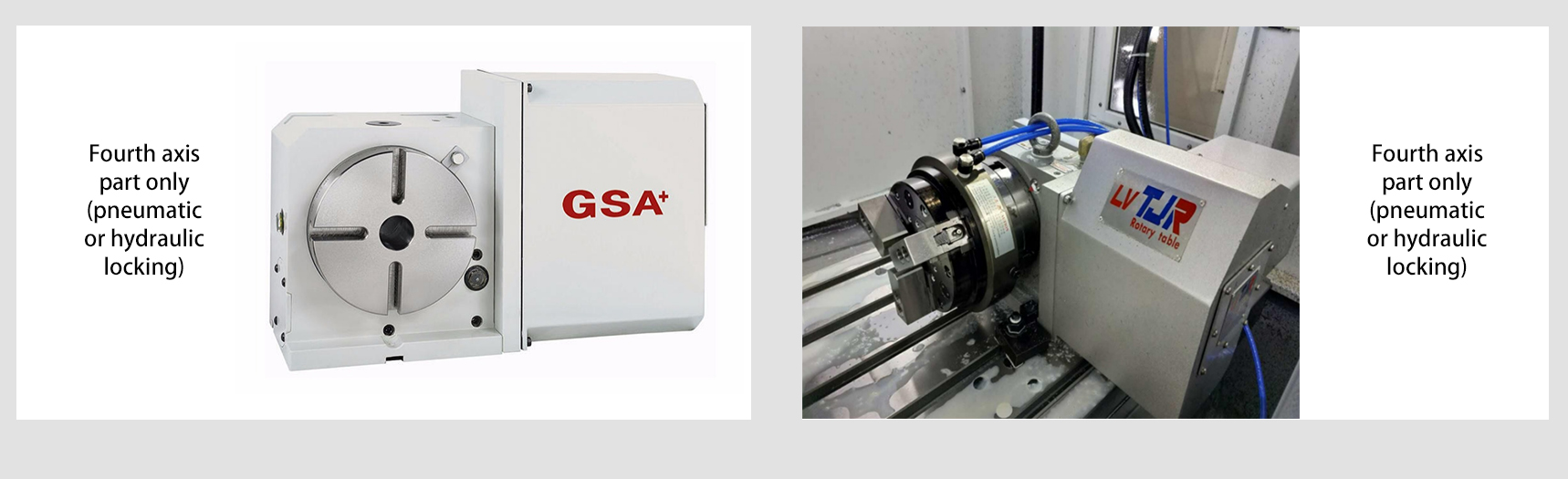

VIII.For the full range of VMC-850 vertical machining centers, an optional fourth axis is available as additional equipment:

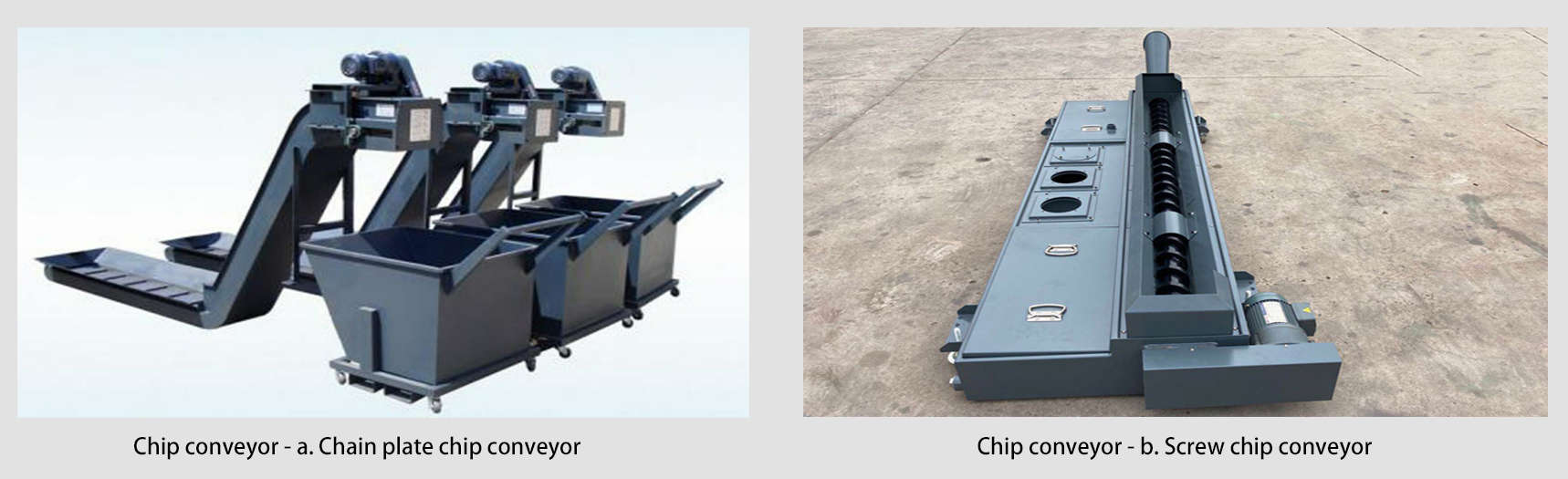

IX. For the full range of VMC-850 vertical machining centers, an optional chip conveyor is available as additional equipment:

X. For the full range of VMC-850 vertical machining centers, an optional fifth axis is available as additional equipment:

| Model |

VMC-850A (Three Linear Guideways)

|

VMC-850B (Two Linear And One Hard)

|

VMC-850C (Three Hard Guideways)

|

|---|---|---|---|

| Spindle | |||

| Spindle Taper | BT40 | BT40 | BT40 |

| Spindle Speed (rpm/min) | 8000 (Direct drive 15,000 rpm, optional) |

8000 (Direct drive 15,000 rpm, optional) |

8000 (Direct drive 15,000 rpm, optional) |

| Main Drive Motor Power | 7.5kw | 7.5kw | 11kw |

| Power Supply Capacity | 20 | 20 | 20 |

| Processing range | |||

| X-axis Travel | 800mm | 800mm | 800mm |

| Y-axis Travel | 550mm | 500mm | 500mm |

| Z-axis Travel | 550mm | 500mm | 500mm |

| Worktable Size | 550X1000mm | 500X1000mm | 500X1050mm |

| Maximum Load of Worktable | 500kg | 500kg | 600kg |

| Workbench T-slots (quantity – size * spacing) |

5-18*90 | 5-18*90 | 5-18*90 |

| The distance between the spindle axis and the column | 590mm | 560mm | 550mm |

| Distance from the spindle end face to the workbench | 110-660mm | 110-610mm | 105-605mm |

| Processing parameters | |||

| Rapid traverse along X/Y/Z axes, meters per minute | 36/36/36 | 24/24/15 | 15/15/15 |

| Working feed, millimeters per minute | 1-10000 | 1-10000 | 1-10000 |

| Numerical control system | |||

| FANUC MF3B |

X-axis: βiSc12/3000-B

Y-axis: βiSc12/3000-B

Z-axis: βis22/3000B-B

Spindle: βiI 8/12000-B

|

X-axis: βiSc12/3000-B

Y-axis: βiSc12/3000-B

Z-axis: βis22/3000B-B

Spindle: βiI 8/12000-B

|

X-axis: βiSc22/2000-B

Y-axis: βiSc12/2000-B

Z-axis: βis22/2000-B

Spindle: βiI 12/10000-B

|

| SIEMENS 828D |

X-axis:1FK2306-4AC01-0MB0

Y-axis:1FK2306-4AC01-0MB0

Z-axis: 1FK2208-4AC11-0MB0

Spindle: 1PH3105-1DG02-0KA0

|

X-axis:1FK2306-4AC01-0MB0

Y-axis:1FK2306-4AC01-0MB0

Z-axis:1FK2208-4AC11-0MB0

Spindle:1PH3105-1DG02-0KA0

|

X-axis:1FK2308-4AB01-0MB0

Y-axis:1FK2308-4AB01-0MB0

Z-axis:1FK2208-4AC11-0MB0

Spindle:1PH3131-1DF02-0KA0

|

| Mitsubishi M80B |

X-axis: HG204S-D48

Y-axis: HG204S-D48

Z-axis:HG303BS-D48

Spindle: SJ-DG7.5/120

|

X-axis:HG204S-D48

Y-axis:HG204S-D48

Z-axis:HG303BS-D48

Spindle:SJ-DG7.5/120

|

X-axis:HG303S-D48

Y-axis:HG303S-D48

Z-axis:HG303BS-D48

Spindle:SJ-DG11/120

|

| Instrument System | |||

| Tool Magazine Type and Capacity | Disc type (manipulator type) 24 pieces | Disc type (manipulator type) 24 pieces | Disc type (manipulator type) 24 pieces |

| Tool Holder Type | BT40 | BT40 | BT40 |

| Maximum Tool Diameter / Adjacent Empty Position | Φ80/Φ150mm | Φ80/Φ150mm | Φ80/Φ150mm |

| Maximum Tool Length | 300mm | 300mm | 300mm |

| Maximum Tool Weight | 8kg | 8kg | 8kg |

| Accuracy | |||

| Repeatability of X/Y/Z Axes | 0.008mm | 0.008mm | 0.008mm |

| Positioning Accuracy of X/Y/Z Axes | 0.006mm | 0.006mm | 0.006mm |

| X/Y/Z Axis Guideway Type | Linear guide X-axis: 35 Y-axis: 45 Z-axis: 45 |

Linear guide + Hard guide X-axis: 45 Y-axis: 45 Z-axis: Hard guide |

Hard guideway |

| Screw Specification | 4016/4016/4016 | 4012/4012/4012 | 4010/4010/4010 |

| Aspect | |||

| Length | 2600mm | 2600mm | 2600mm |

| Width | 2880mm | 2500mm | 2500mm |

| Height | 2750mm | 2650mm | 2650mm |

| Weight | 5500kg | 6200kg | 5500kg |

| Required Air Pressure | ≥0.6MPa ≥500L/min(ANR) | ≥0.6MPa ≥500L/min(ANR) | ≥0.6MPa ≥500L/min(ANR) |

TAJANE Service Center

TAJANE has a CNC machine tool service center in Moscow. Service experts will assist you in guiding the installation, debugging, equipment diagnosis, maintenance, and operation training of CNC machine tools.The service center has a long-term reserve of spare parts and consumables for the entire range of products.

.jpg)