Manual knee milling machine MX-4HG

MX-4HG manual knee milling machine uses the worktable to drive the workpiece to move, and the high-speed spindle drives the tool to rotate for cutting. Manual knee milling machine is widely used in small batch parts processing such as machining, moulds, instruments, meters, etc.

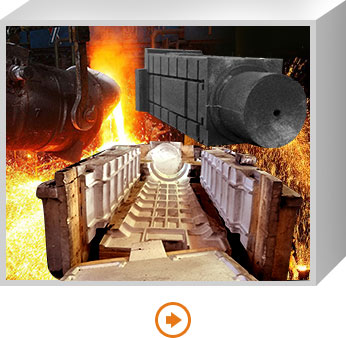

Taiwan's original drawings manufacturing process

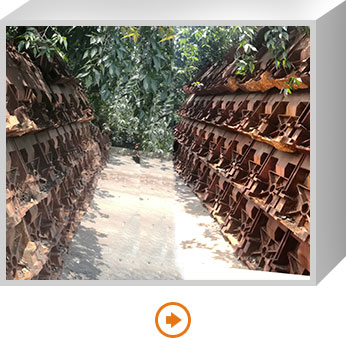

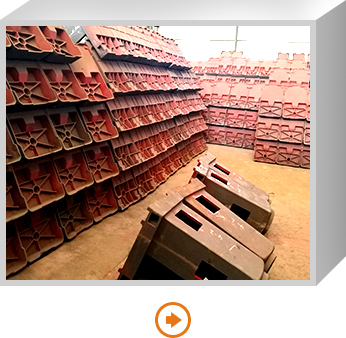

Mihanna Casting Technology

Elimination of internal stress

Tempering heat treatment

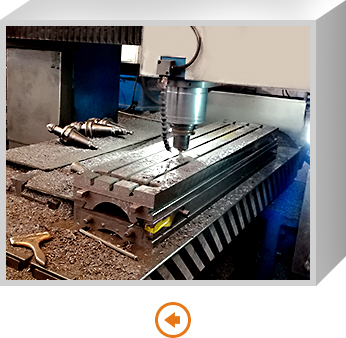

Precision machining

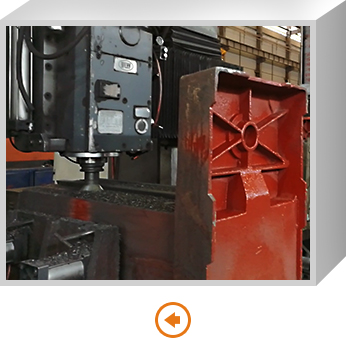

Lifting table processing

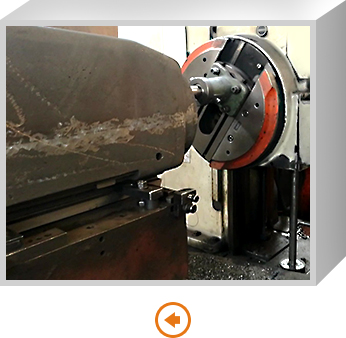

Lathe processing

Cantilever machining

High frequency quenching

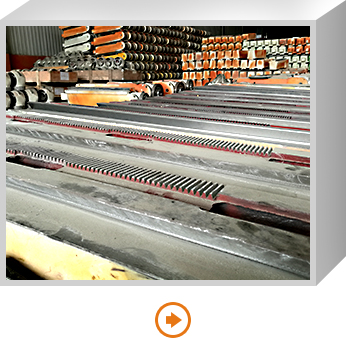

Fine carving

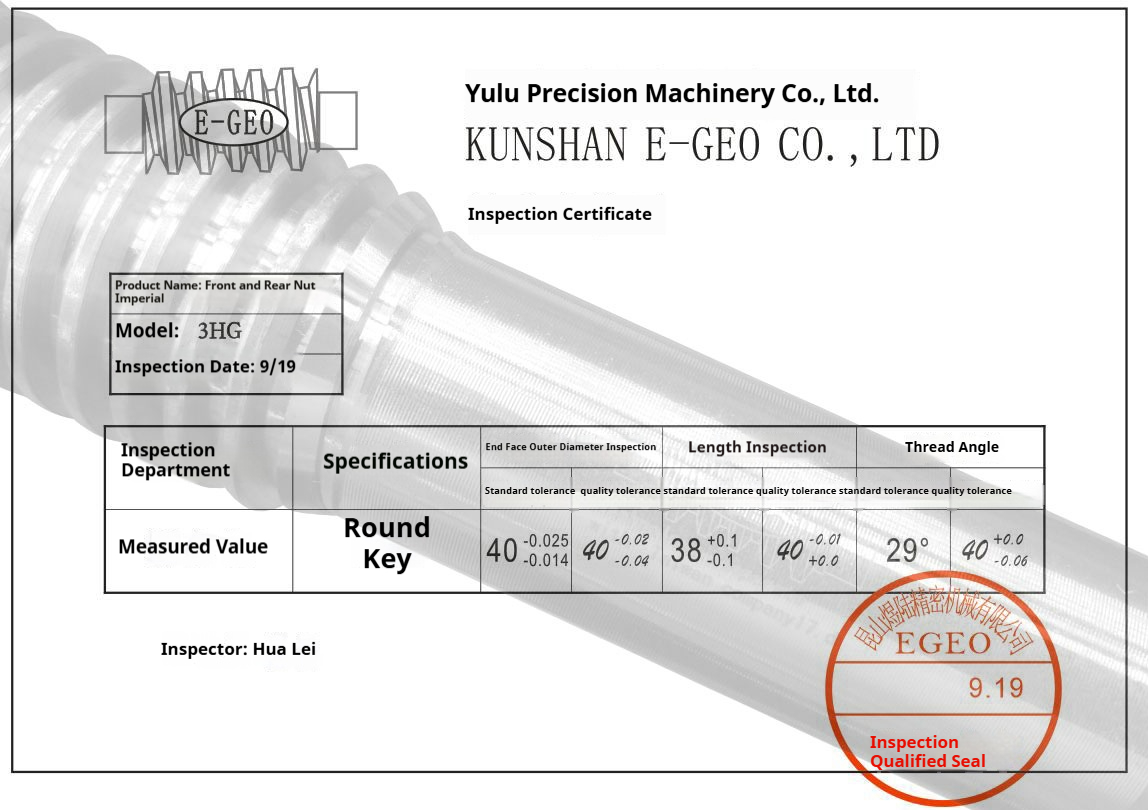

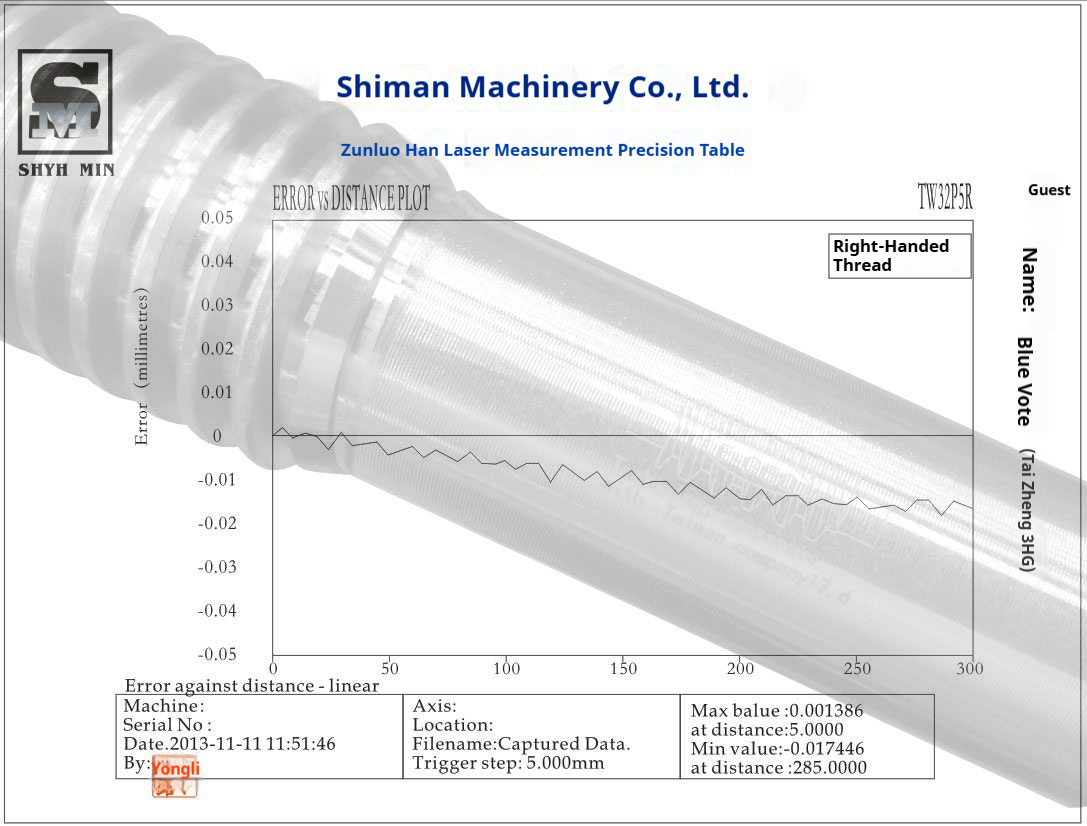

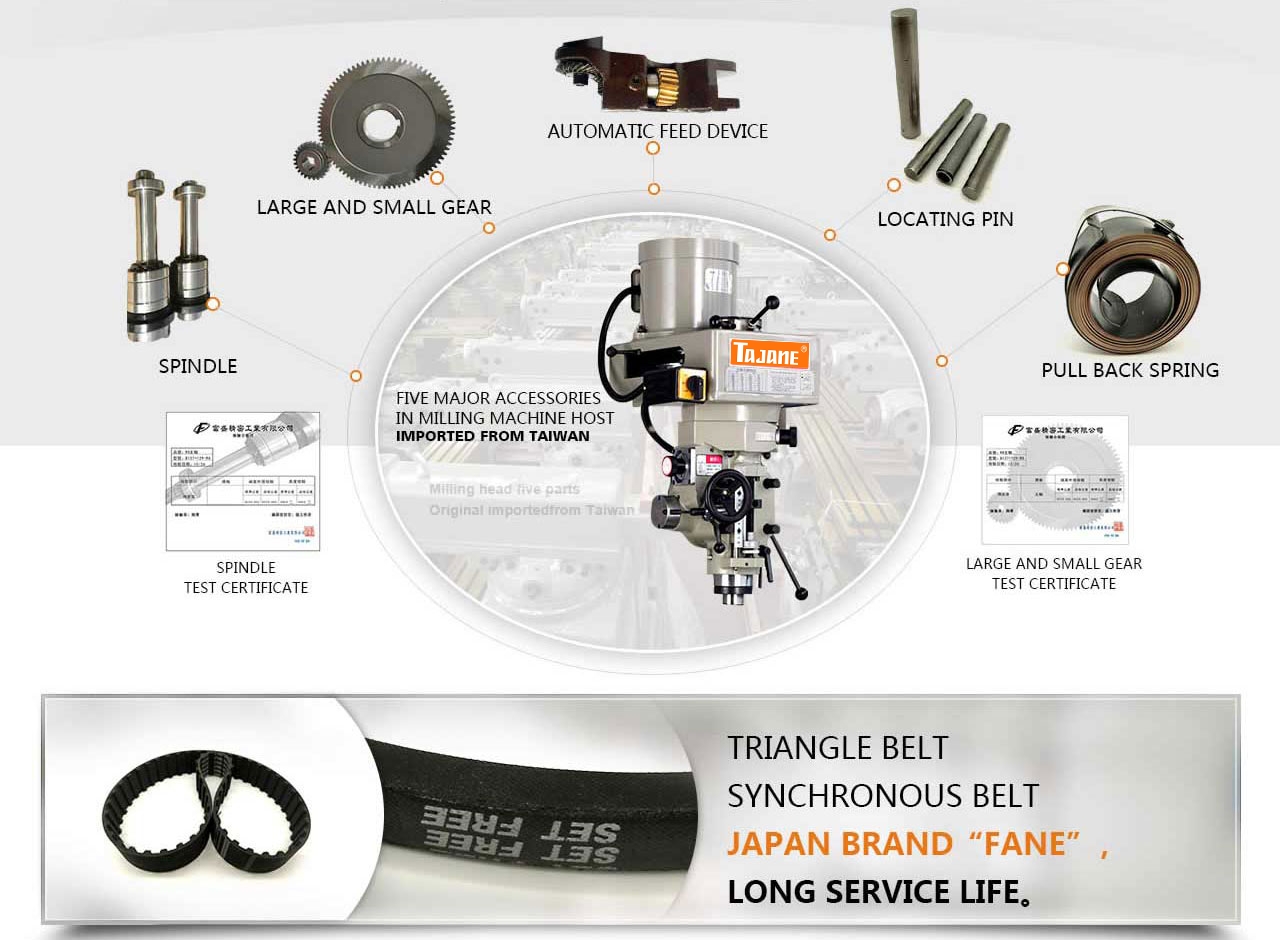

Taiwan's original boutique parts, the only guarantee of the quality of precision

Milling machine accessories meet different processing needs

R8 Chuck set 12piece set

►φ03/4/5/6/8

►φ10/12/14/15

►16/18/20

Delos Scale

Wide-band Voltage : AC80-250V ◀

Measurement accuracy: 0.005mm ◀

Accurate Display of Machining Dimensions ◀

QM-160 Precise Flat nose pliers

►Super clamping force

►Precision and durability

►Famous brand

58 Precision combination pressure plate suit

►Super clamping force

►Precision persistence

►German quality

Electronic power feeder

► ALSGS, a Taiwanese brand

► CVT acceleration

► Smooth driving

► Quick response

Environmental protection Protection cover

Integral drill chuck

► Integral

► Automatic locking

► Size :Φ O.5~16mm

Machine tool isolator

► Super Supporting Force

► Stable shock absorption

► Durable

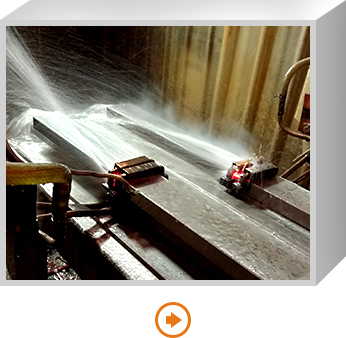

Cooling system

► Delay cutter life

► Oil chip separation

► Large water yield

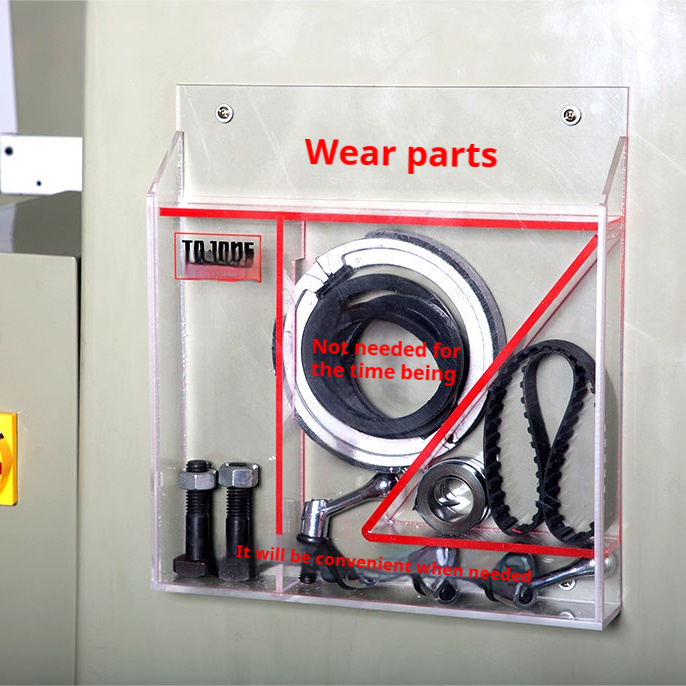

PRESENT NINE CONSUMABLES TO SOLVE YOUR WORRIES

Pull rod/1

Triangle belt

Synchronous be

Return spring

Locking bolt

Chip protection

Locking handle

Motor carbon brush

Brake pads

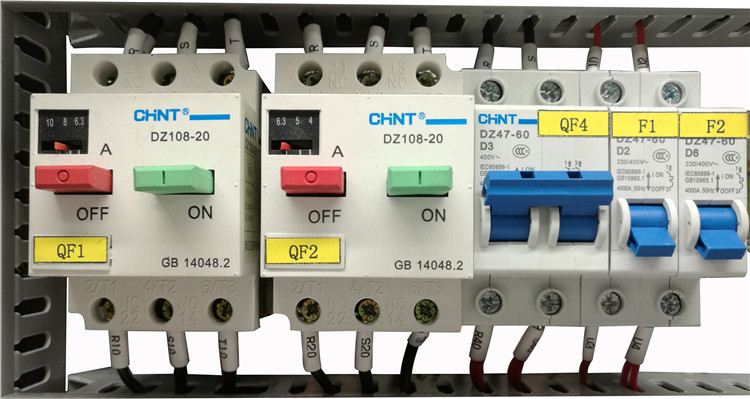

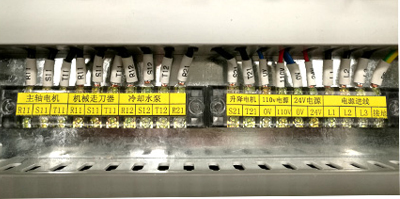

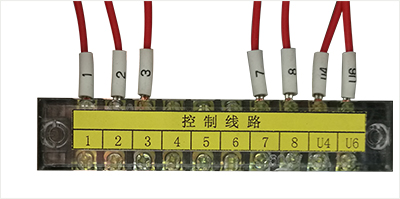

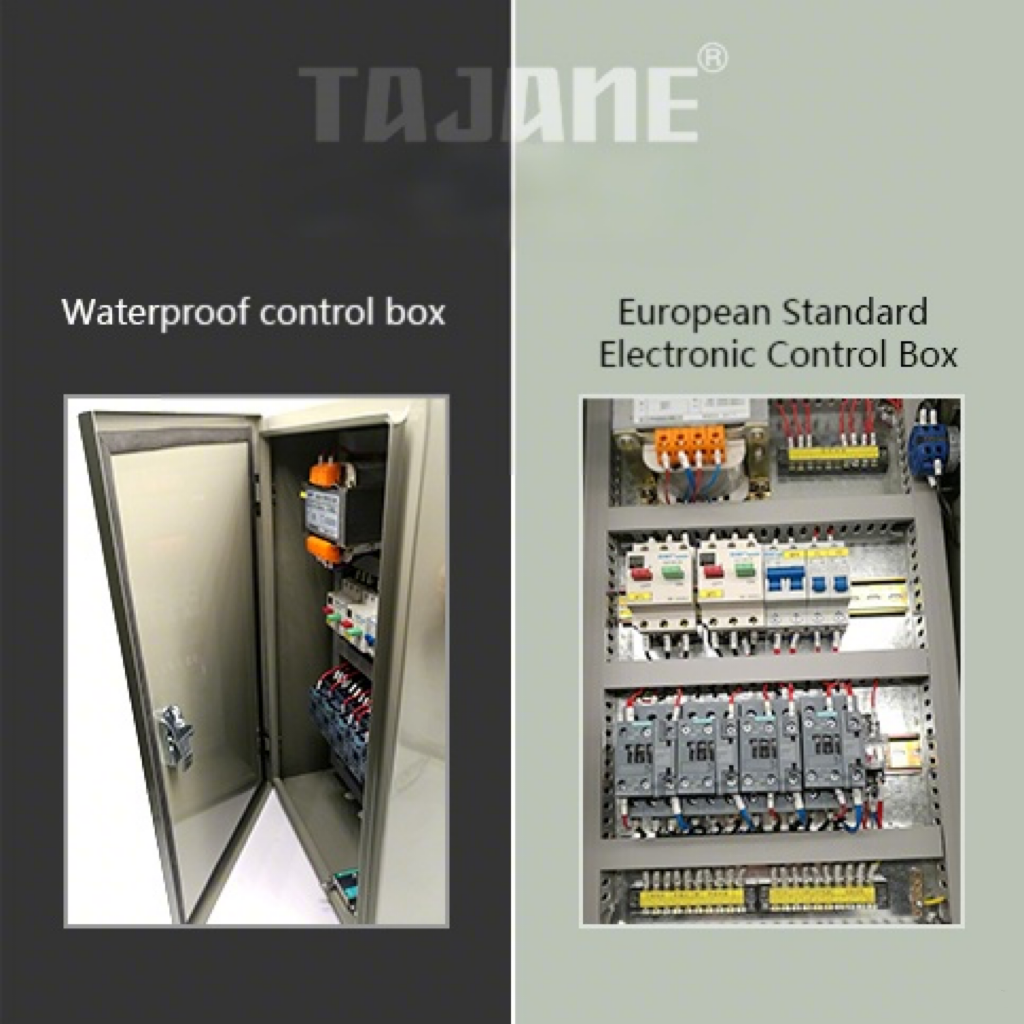

safety of electrical appliances

Using European Standard Cable

Main cable2.5MM², Control cablel 1.5MM²

Electrical components are Siemens And CHNT

Identification clear

Convenient maintenance

Earthing protection

Door s open and power will be cut off.

Press emergency stop Power cut off.

Power off switch

Master switch Power Indicator Lamp

Earthing protection

Emergency stop button

packing

Steel belt fastener Wood packaging ,

Locking connection Firm tensile strength.

Free transportation in China

Undertaking transportation insurance.

Perfect after-sales service

Mechanical Parts and Electrical Appliances

Guaranteed for 12 Months

| Model | MX-4HG |

| Work Table | 1270 x 254mm |

| Max. Longitudinal Travel(X-axis) | 810mm (Automatic feed) |

| Max. Vertical Travel(Y-axis) | 360mm |

| Max. Cross Travel(Z-axis) | 360mm |

| Guide rail form(X、Y、Z) | ▲■▲ |

| Distance from spindle to table | 470mm |

| Horsepower | 3HP |

| Voltage | Three phase380V(或220V、415V、440V) |

| Frequency | 50/60 |

| Spindle Taper Type | R8 or (NT30) |

| Step Number (Low Range) (High Range) | 16steps 70、110、180、270、600、975、1540、2310rpm 140、220、360、540、1200、1950、3080、5440rpm |

| Spindle Quill Travel | 120mm |

| Quill Feed/Quill O.D. | 0.04、0.08、0.15/85.725mm |

| T-Slot Slot No.×Width×Pitch | 3x 16x 65mm |

| Ram Travel | 520mm |

| Machine Dimensions | 1650x1650x1900 |

| Weight | 1450kg |

Accessories

● X, Y, two-axis grating ruler

● X, direction electronic tool feeder

● QH160 precision flat pliers

● 58-piece set of M12 combined pressure plate

● 12-piece set of high-precision R8 collet set

● Cooling system and water pan

● A set of powerful integrated drill chuck

● A set of environmentally friendly protective covers

Random wearing parts (gift)

● Two pieces of milling head bolts

● Two carbon brushes for knife feeder

● One piece of milling head brake pad

● One piece of automatic knife spring

● One V-belt

● One synchronous belt

● One rod

● A set of anti-dandruff leather

● Workbench locking handle four pieces

Special accessories

● Rotary table

● dividing head

● Parallel blocks